Researchers Develop Contact Lens to Prevent Dry Eye Disease

A collaborative team from the Terasaki Institute for Biomedical Innovation (TIBI) has developed a contact lens prototype that is specifically designed to prevent contact lens-induced dry eye (CLIDE). The new lens helps treat this condition by enabling tear flow in response to typical eye blinking.

The research is published in the journal Small.

30–50% of the 140 million people who wear contacts get CLIDE globally. The disease is caused by an inadequate tear flow from the contact lens' outer surface to the area behind the lens. As a result, there is excessive tear evaporation, which causes all the issues with CLIDE.

Current treatment options for this condition include rewetting drops, gels, or lubricants, more frequent lens replacement, or changes in the lens material. Additionally, there are eyelid therapies including eyelid massages and warm compresses.

In more severe cases, punctum plugs—devices put into tear ducts to prevent drainage—as well as manual stimulation of the tear glands can be used. Efficacy varies among these treatments, however, there may also be potentially harmful accumulations of drugs in the body, and the non-user-friendly methods contribute to patient noncompliance.

Previous Attempts to Treat CLIDE Were Found Ineffective

There have also been previous attempts to use contact lenses to treat dry eye syndrome, such as self-moisturizing lenses triggered with metallic electrodes and graphene-coated lenses designed to reduce moisture loss. However, these approaches can jeopardize patient safety and comfort and are expensive and impractical.

The strategy employed by the TIBI team makes use of a contact lens design that includes microchannels to promote tear flow mobility and flow to prevent dry eye. No external devices are required because the pressure can be applied by natural eye blinking.

The researchers used a time-saving technique to create their contact lens prototype. Their lens mold was made of a silicone polymer mixture, which made it possible to remove the lens that had been cast on it simply by gently bending the mold.

Earlier techniques required soaking the lens for twelve hours in hot water to remove it. The method produced lenses that could be thirty times smaller than previous lenses, as well as high-quality, smooth microchannels. A custom device was used to fabricate reservoirs at the ends of each microchannel for the inflow and outflow of liquids.

Researchers Use Innovative Methods for Lens Design

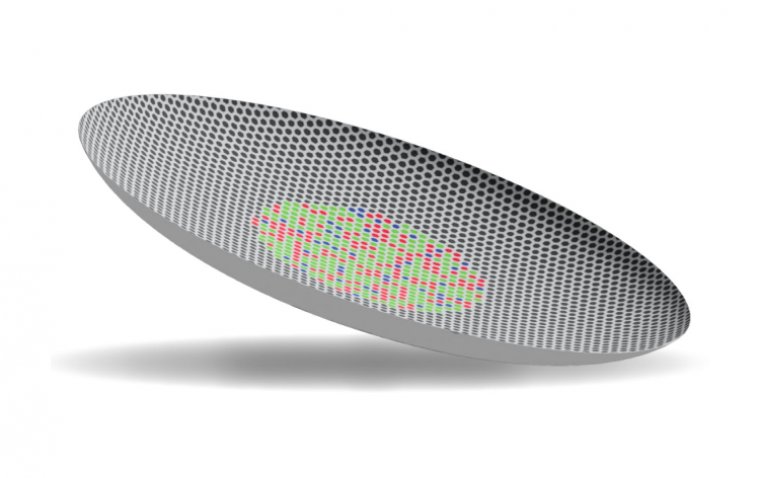

Innovative techniques were also used when encapsulating the microchannels in a sandwich-like assembly under a capping lens layer. The lenses initially curled because of the dehydration brought on by the process of preparing the two lens surfaces for stronger bonding. This issue was resolved by utilizing water-soluble adhesive to secure the two lenses to holders. In addition to allowing for a more uniform bonding of the lenses, this served to shield them from harm.

.jpg)

Encapsulation of the poly(HEMA) microchannels. The dimensions of microchannels are 200 μm in width and depth, while the encapsulated layer was about 100 μm thick. A glass slide was used as a support. Credit: Small (2022). DOI: 10.1002/smll.202207017

The researchers carefully examined the stability and leaking of their encapsulated microchannel lenses before putting them through a series of tests with a tool they developed to mimic an eyelid blinking. To artificially pressurize the lens and encourage tear production, this mechanism was put into the lens prototype.

After various experiments, a configuration that proved effective was microchannels with square cross-sections arrayed in a novel circular pattern on the lens surface; this was compatible with the function and curvature of the lens and allowed for optimum liquid flow.

In order to fight dry eye condition, the team gave a proof-of-concept demonstration that its lens could direct tear flow coming from the lens surface to the underside of the lens. The scientists measured these flows and found that they were caused by low-pressure levels, similar to those that result from typical eye blinking. Further experiments could be devised to test these lenses on animal models and in patients.

"The inventive methods that our team has employed bring a potential solution for millions of people," said Ali Khademhosseini, TIBI's Director and CEO. "It is the hope that we may extend our efforts to bring this solution to fruition."

Reference

Yangzhi Zhu et al, A Microfluidic Contact Lens to Address Contact Lens‐Induced Dry Eye, Small (2022). DOI: 10.1002/smll.202207017

(1).jpg)