Researchers Develop Navigation Function for 3D-Printed Smart Contact Lens

Dr. Seol Seung-Kwon's research team on Smart 3D Printing at KERI, in collaboration with Professor Lim-Doo Jeong's team at Ulsan National Institute of Science and Technology (UNIST), have jointly developed a new core technology for smart contact lenses. The lenses are capable of implementing augmented reality (AR)-based navigation and were created using a 3D printing process.

The study was published as a cover article in Advanced Science.

Smart contact lenses are lenses that are attached to the human eye and provide various types of information. Current research on these lenses is focused on their ability to diagnose and treat health problems. However, some companies, including Google, are currently working on developing smart contact lenses that can display augmented reality (AR). Despite this, the commercialization of these lenses faces several technical challenges, which need to be overcome.

To implement augmented reality (AR) with smart contact lenses, it is necessary to use electrochromic displays that can be operated with low power. The material for the lens, "pure Prussian blue," is attracting attention due to its cost competitiveness and ability to quickly transition between colors and provide sharp contrast. In the past, this color was applied as a film on the substrate using electric plating, which limited the ability to produce advanced displays capable of expressing various types of information, such as letters, numbers, and images.

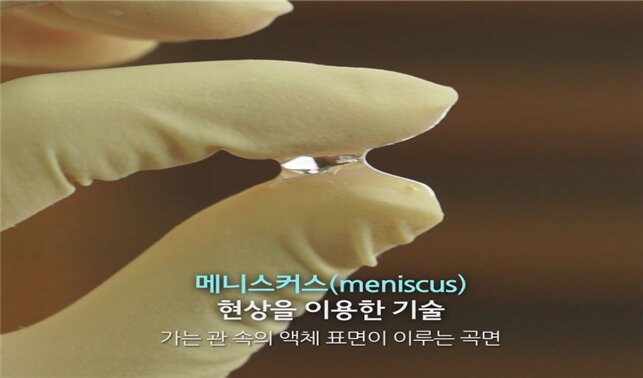

Ink Meniscus Enables AR Achievement without Voltage

The KERI-UNIST team has achieved a significant milestone in developing a technology that enables the realization of augmented reality (AR) by printing micro-patterns on a lens display using a 3D printer, without the need for voltage. The key to this achievement is the meniscus of the ink used in the process. This refers to the formation of a curved surface on the outer wall, without water droplets bursting due to capillary action when the droplets are gently pressed or pulled with a certain pressure.

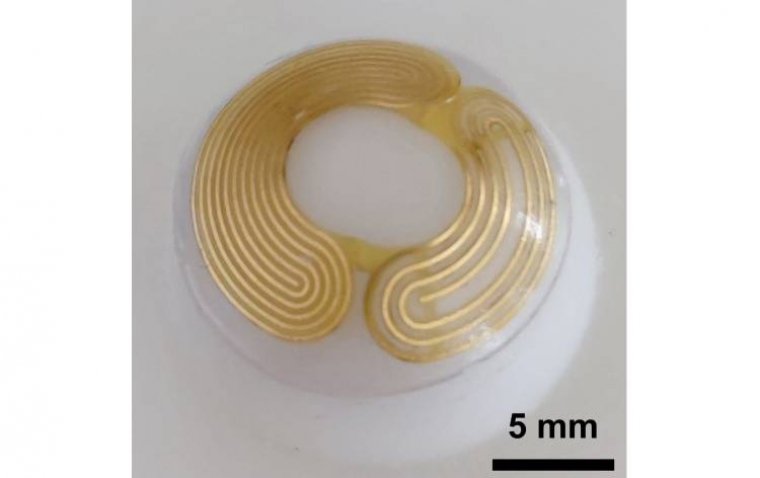

![Crystallization of FeFe(CN)6 occurs on the substrate in a region confined by the meniscus, forming the uniform pattern. FeFe(CN)6 pattern is converted to the PB (Fe4[Fe(CN)6]3) via thermal reduction. Credit: Korea Electrotechnology Research Institute](/files/images/smart-contact-lens-wit-1.jpg)

Crystallization of FeFe(CN)6 occurs on the substrate in a region confined by the meniscus, forming the uniform pattern. FeFe(CN)6 pattern is converted to the PB (Fe4[Fe(CN)6]3) via thermal reduction. Credit: Korea Electrotechnology Research Institute

During the printing process, Prussian blue is crystallized by allowing the solvent to evaporate in the meniscus that forms between the micronozzle and the substrate. This is achieved through the formation of a meniscus of acidic-ferric-ferricyanide ink on the substrate when the ink-filled micronozzle and substrate come into contact. At room temperature, the precursor ions (Fe3+ and Fe(CN)3-) undergo spontaneous reactions, leading to the heterogeneous crystallization of FeFe(CN)6 on the substrate within the meniscus. Simultaneously, solvent evaporation takes place on the surface of the meniscus.

During the printing process, when water evaporates from the meniscus, water molecules and precursor ions move toward the meniscus surface, creating convective flow that leads to a preferential accumulation of precursor ions in the outer part of the meniscus. This phenomenon is critical in inducing edge-enhanced crystallization of FeFe(CN)6, which is essential for controlling the factors that influence the crystallization of FeFe(CN)6 during the printing process. This is necessary to achieve uniformly printed patterns of Prussian blue on the substrate.

Meniscus Phenomenon: A New Approach for Crystal Formation on Substrates

Unlike conventional electroplating, where the substrate had to be a conductor for voltage application, the use of the meniscus phenomenon offers a significant advantage in that there is no restriction on the type of substrate used. This is because crystallization occurs through the natural evaporation of the solvent, and voltage application is not required.

Using precise nozzle movements, the research team is able to continuously perform the crystallization of Prussian blue, resulting in the formation of micro-patterns. These patterns can be formed on both flat and curved surfaces. The team's micro-pattern technology is capable of producing very fine patterns with a resolution of 7.2 micrometers, and it can be applied to smart contact lens displays for AR, as the resulting color is continuous and uniform.

The primary application area for the smart contact lenses is expected to be navigation. By wearing the lenses, AR-based navigation can be displayed directly in front of the user's eyes. Additionally, popular games like "Pokemon Go" can be enjoyed through the lenses without the need for a smartphone.

Image showing meniscus phenomenon. Credit: Korea Electrotechnology Research Institute

Dr. Seol Seung-Kwon's of KERI said, "Our achievement is a development of 3D printing technology that can print functional micro-patterns on non-planner substrate that can commercialize advanced smart contact lenses to implement AR." He added, "It will greatly contribute to the miniaturization and versatility of AR devices."

For a deeper understanding of the role and future prospects of 3D printing in developing such innovative technologies, particularly in ophthalmology, readers can explore more in-depth insights at "The Role of 3D Printing Today and Tomorrow." This article delves into how 3D printing is shaping the future of medical devices and treatments, offering a glimpse into a world where cutting-edge technology and healthcare converge to enhance human capabilities.

Reference

Je Hyeong Kim et al, Meniscus‐Guided Micro‐Printing of Prussian Blue for Smart Electrochromic Display, Advanced Science (2022). DOI: 10.1002/advs.202205588

(1).jpg)