Researchers Develop Faster, Cheaper 3D Printing Technique for Artificial Eyeballs

A team of biomedical and ophthalmological researchers from various European institutions, in collaboration with computer graphics specialists, has unveiled a novel technique for 3D printing artificial eyeballs. Published in the esteemed journal Nature Communications, their innovative approach promises to revolutionize the process, offering a faster, more accurate, and cost-effective alternative to conventional methods.

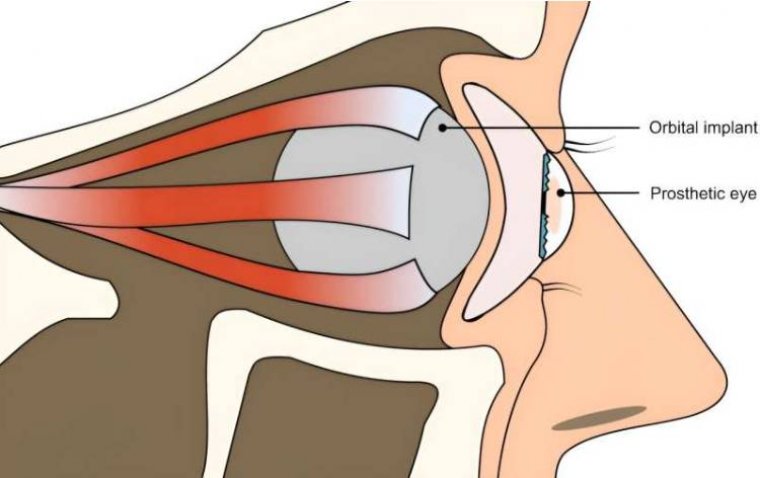

"People who lose an eye due to disease or injury face not only the loss of sight but also the challenge of how to present themselves," explains the team. Traditionally, individuals have had two options: wearing an eye patch or inserting an artificial eye into the empty socket. However, the current process of crafting artificial eyes involves molding polymethyl methacrylate into an eyeball shape—a laborious and expensive endeavor. Moreover, this method is prone to errors, leading to discomfort or unnatural appearances.

The Power of 3D Printing

In their pioneering work, the research team turned to 3D printing technology to streamline the process, significantly reducing both time and cost while improving the likelihood of a proper fit. The first step involved identifying a suitable material akin to polymethyl methacrylate for printing. Subsequently, optical coherence tomography was employed to scan the empty eye socket, with the obtained data fed into a computer modeling application. This software accurately simulated the eye socket and how the artificial eyeball would interact with the patient's eyelids. The resulting digital model was then translated into physical form through 3D printing.

After printing, the artificial eye underwent polishing in a tumbler, followed by washing in an ultrasonic bath and rigorous toxicity testing to ensure safety for prospective patients. To validate their technique, the team distributed 10 test artificial eyeballs to 10 patients. Remarkably, eight recipients reported successful outcomes in terms of appearance and comfort, underscoring the potential of this innovative approach.

"While more work is needed, we are confident that we have discovered a superior method for producing artificial eyeballs," concludes the research team. This breakthrough not only holds promise for enhancing the quality of life for individuals with eye injuries or diseases but also represents a significant advancement in the field of ophthalmology.

Use of 3D Printing in Ophthalmology

3D printing technology has emerged as a game-changer in the field of ophthalmology, offering innovative solutions for various eye-related conditions. From crafting artificial eyeballs with enhanced precision to developing customized ocular implants and prosthetics, 3D printing has revolutionized the way ophthalmic devices are designed and manufactured. This advanced manufacturing technique allows for the creation of intricate structures tailored to the specific needs of individual patients, leading to improved outcomes and patient satisfaction.

Moreover, the advancements in 3D printing are not just about the present but also shape the future of eye care. To further explore this, consider the insights offered in "The Role of 3D Printing Today and Tomorrow", which delves into how current innovations lay the groundwork for future breakthroughs in ophthalmology and beyond. This continuous evolution highlights the transformative potential of 3D printing in enhancing patient care and pioneering new frontiers in medical science.

Reference

Johann Reinhard et al, Automatic data-driven design and 3D printing of custom ocular prostheses, Nature Communications (2024). DOI: 10.1038/s41467-024-45345-5

(1).jpg)